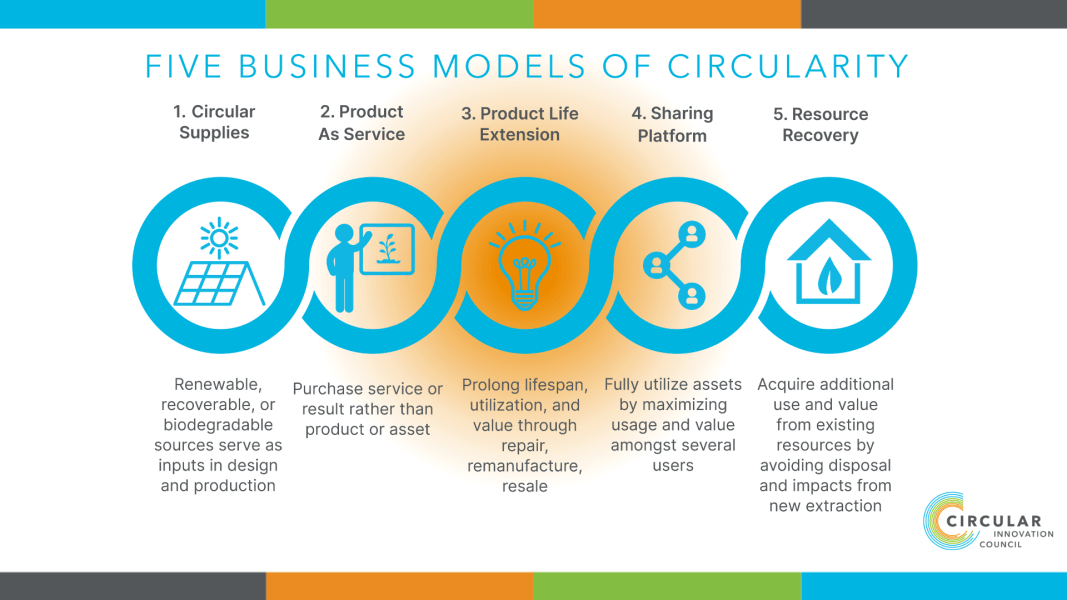

In our Circular Business Models series, we delve into the role of various business models in accelerating a circular economy. Previously we discussed Circular Supplies and the actionable steps you can take in your business to support a circular supplies model. In this article, we focus on Product Life Extension, and the importance of prolonging the life of a product to minimize environmental impacts.

In a world increasingly aware of the consequences of our actions on the environment, the idea of repairing, remanufacturing, and refurbishing products is gaining attention. Repairing, refurbishing, and remanufacturing was once an integral part of our culture, but since the 1950s, it has taken a backseat with the rise of throw away culture. However, as the circular economy takes center stage, there is a growing realization, particularly among governments, that extending the life of products is not only environmentally sound and effective at mitigating climate change but also economically savvy in the long term.

Understanding product life extension and its role in reducing embodied emissions

The product life extension circular business model is built on extending the current life cycle of a product or asset by repairing, upgrading, refurbishing, and remanufacturing to retain as much of their value as possible so they continue to be useful.

Embodied emissions, also known as Scope 3 emissions, refer to the greenhouse gas emissions associated with the extraction of resources, production, use, and disposal of a product or asset throughout its entire lifecycle. When we extend the life of an item instead of replacing it, we eliminate the need for new production. Producing new products requires extracting virgin materials, manufacturing processes, transportation, and packaging, all contributing to carbon emissions embodied in the product or asset. Extending life reduces the demand for new products, thereby reducing the associated embodied emissions.

The benefits of product life extension

Extending the life of products offers many environmental and economic benefits crucial for mitigating climate change, preserving our planet, and generating economic prosperity. Firstly, repairing, refurbishing, and remanufacturing reduces the demand for new production, reducing the need to extract raw materials. In fact, according to the International Resource Panel, remanufacturing uses 80-98% fewer raw materials than traditional manufacturing. There are also substantial economic savings to be realized through the product life extension model. Remanufacturing and refurbishment can generate up to $6 billion annually in Canada. In Europe, it is estimated that the remanufacturing and refurbishment sector could see a cost savings of $630 billion US annually.

Secondly, mining raw materials to produce new products involves various energy-intensive processes. These processes often rely on fossil fuels, which release greenhouse gasses into the atmosphere, contributing to environmental degradation, habitat destruction, social exclusion, and global warming. By minimizing the need for new products, the product life extension can help protect natural resources and ecosystems, and reduce energy consumption and carbon emissions. Remanufacturing, for example, uses only 15% of the energy required for new products and can reduce emissions by 57-87%.

Thirdly, the product life extension model prevents items from entering landfills, which, in most instances, are reaching their carrying capacity. By remanufacturing, repairing, and extending the lifespan of products, waste is reduced by 70-90%.

Envirotech is a perfect example of a company leading the circular economy transition through product life extension. Based in Mississauga and serving North America, Envirotech is a remanufacturer and dealer of office products that leverages circular business models to engage greater sustainability outcomes for customers large and small.

By adopting the product life extension model, Envirotech and its clientele conserve natural resources. Their office furniture remanufacturing extends the life of resources already in use, such as wood, steel, aluminum, plastics, and fibre, maximizing their utility. An average office task chair has an estimated carbon footprint of 72 kilograms C02e, which is the equivalent of driving more than 360 kilometers. Moreover, the lifespan of an average office chair can be as brief as six months.

“Over the past decade, there has been a significant reduction in the average length of office leases across North America,”. “For instance, in Toronto, lease durations have shrunk from 5.7 years in 2019 to 3.5 years in 2023. This shift leads to more frequent office refurbishments. Sadly, less than 10% of office furniture is repurposed beyond its initial setting. Given the swift turnover of furniture, research suggests it can contribute up to 30% of a building’s embodied carbon footprint,” says Andy Delisi, Vice President, Sales, at Envirotech Office Systems Inc

A higher quality chair that can be remanufactured can remain in use for 15-20 years. If we apply the average office furniture turnover of every 3.4 years, this would result in five times less embedded carbon footprint.

“In 25 years we have remanufactured more than 40,000 workstations/desks and 100,000 chairs, which is more than 11 million kilograms of furniture diverted from landfill,” says Delisi.

Mr. Delisi also points out that “our task chairs & workstations are reupholstered, cleaned, and rebuilt to like-new condition. The products are remanufactured to last and we offer a lifetime warranty on our workstations & 10 year warranty on task seating. Through our unique process, we keep thousands of kilograms from ever going to waste every year, while maximizing our clients’ economic savings with top-of-the-line products from world class manufacturers.”

While waste reduction is fundamental to circularity, embodied carbon in manufacturing also plays a significant role in carbon footprints. Remanufacture and refurbishment reduces the pollution caused by the manufacturing process, and lessens the release of carbon monoxide and dioxide, sulfur and nitrous oxides, as well as volatile organic compounds.

This past summer, Envirotech was engaged by Kraft-Heinz to furnish their new Canadian Headquarters. Envirotech’s comprehensive refurbishment, reuse and remanufacturing procurement strategy allowed Kraft to meet both their ESG initiatives and reduce overall project budget. The project realized close to one million dollars in cost savings and reduced the embodied carbon footprint by roughly 65% compared to new furniture only. This project is one of many over Envirotech’s 27 years of service that demonstrates the real value and benefits of using the product life extension model to address embodied emissions and resource efficiency. It is an example that can be easily adopted by the public sector where the impact would be significant.

Circular procurement enables product life extension

Governments play a crucial role in our quest for circularity and hold the key to accelerating its adoption. As the largest public procurers of goods and services, governments can leverage buying power to trigger market transformation and adopt business models like product life extension.

Circular procurement offers a strategic and purposeful opportunity to reduce carbon emissions, minimize risk, and save on long- and short-term costs. By embedding circular principles into procurement that create circular demand, governments create an enabling environment for product life extension circular model that reduces embodied emissions and fosters economic growth, job creation, and social well-being.

Tips for incorporating the product life extension model into procurement practices.

Incorporating the product life extension model into current procurement practices can seem daunting at first, especially for those unfamiliar with the circular model. However, considering the above tips and a slight change in mindset, anyone can embrace circularity and contribute to a more sustainable future.

In our Circular Business Models series, we delve into the role of various business models in accelerating a circular economy.

Embodied Carbon: The New Frontier Accelerating the Circular Economy and Fighting Climate Change – Introduction article to the series discussing embodied carbon.

Accelerating Canada’s Transition to a Circular and Low Carbon Economy. Circular Business Models: Circular Supplies. – For businesses to understand the benefits and importance of a Circular Supplies business model.

Stay tuned for the upcoming articles through our website, social media (Facebook, LinkedIn, Instagram, & Twitter), or email list!

Circular Innovation Council is a registered charity.

Charity Registration Number: 119112118 RR 0001