Circular Innovation Profiles is our feature series that showcases innovators and individuals that are helping to accelerate Canada’s circular economy by adopting circular business models and solutions.

Nearly everything we produce and consume can be recycled if it can be broken down to its basic properties: even though they are custom molded, dentures can be broken down to recover precious metals for reuse; chewing gum can be remolded into soles for shoes; finished drywall can be recovered and processed into new drywall.

The caveat, of course, is that recycling requires a clean and dedicated supply of material.

While modern material recycling facilities are advanced mechanical systems that can sort a variety of material, separating dentures, gum, and dry from paper, cans, and pop bottles is an engineering feat that has yet to be accomplished.

Engineering has been able to accomplish in other areas, however, never ceases to amaze. Take the airbag, a standard piece of safety equipment mandatory in every car since 1999.

When triggered by a collision a sensor sends an electric signal to start a chemical reaction that inflates the airbag with nitrogen gas within 50 milliseconds – faster than a blink of an eye.

While a fully deployed airbag can be easily separated and recycled, an undeployed airbag is considered hazardous waste, as well as certain kinds of seat belts that contain an igniter. That is where Lacero Solutions, a Mississauga-based innovator, comes in.

We were inspired by a client who mentioned they had an excessive number of airbags that needed management, and that no one wanted the material. Scrap metal processors will not take live airbags because igniters damage furnaces and shredders, explains Keshav Kochhar, CEO and co-founder, Lacero Solutions. As for the supply, there was a recall of 100 million airbags world-wide, with more than 5 million recalled airbags in Canada alone.

Safety is paramount for auto manufacturers, and there’s a risk of recalled airbags being reintroduced back into market. Auto shops in developing nations have been known to acquire grey market material because it is considerably cheaper than buying new.

With a mix of ingenuity, collaboration, and a background in chemical engineering, Keshav worked with a small team to develop a method to safely separate airbag components for recovery, and institute a robust tracking and reporting system that logs material from initial intake to final disposition.

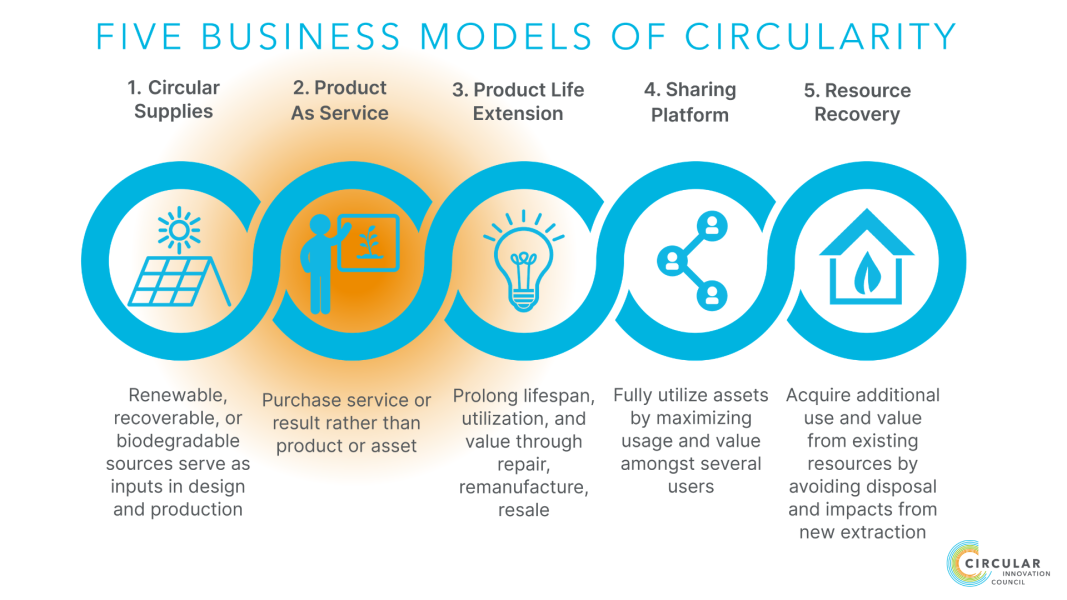

Lacero also saw an opportunity to apply innovation to other hard-to-recycle products, and since 2018, through the Resource Recovery circular business model, processed and diverted more than 275,000 airbags and seatbelts – 302,999 kilograms of scrap metal, 6,800 kilograms of copper and plastic, as well as 96,161 kilograms of cardboard – from disposal. As a Circular Supply, some of the recovered components, such as scrap metal and copper, have been reintroduced into the supply chain for use in steel and automotive industries.

We take a lot of pride in identifying solutions to recover materials that would otherwise be landfilled. As a part of the Canadian manufacturing sector, we know there is so much material out there that may not have a recovery solution. Part of the fun – and challenge – is to uncover opportunity and discover material to keep in constant circulation. We’re able to do that with airbag and seatbelt components, and we’re always on the lookout for the next device that was once considered unrecyclable.

By joining Circular Innovation Council, we hope to connect with like-minded entrepreneurs and engineers to collaborate and celebrate resource recovery in ways that were never even thought possible five, even ten years ago. Innovation is moving faster than ever, and for every new product brought to market we need to scale technologies to recover them just as quickly. Our vision is to scale-up sustainably and introduce more solutions to divert and recycle all kinds of hazardous waste.

Receive selected updates of our activities happening across Canada and the World:

We respectfully acknowledge that we live, work and play on the traditional territory of many Indigenous Nations and we humbly extend our respect to Indigenous individuals, communities and Elders, past and present, as the traditional custodians of this land.

Circular Innovation Council is a registered charity.

Charity Registration Number: 119112118 RR 0001