In Canada, the 1950s and 1960s peaked in industrial activities that scaled up resource extraction to feed a mass production of goods, which led to an increase in waste. This increase led to growing environmental and economic awareness of the impacts from disposal, creating a push for more organized recycling programs.

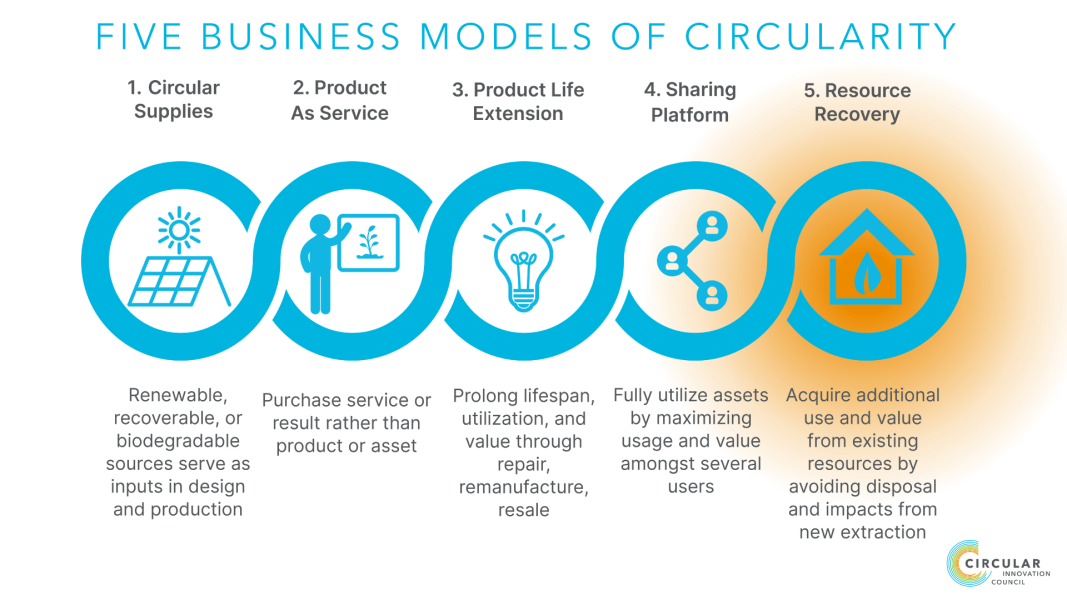

Although steps in the right direction are taken by incorporating blue box systems and other recycling programs, this principle can be scaled further through Resource Recovery models in a circular economy system – using the resources we’ve already extracted (e.g. metals, plastics, food, water) and finding innovative ways to minimize disposal, retain its value, and transform its function back into the production system.

While linear economies only focus on the value of economic growth, circular economies allow multidimensional growth that encompasses economic, environmental, and social dimensions of our production systems, landscapes, and communities.

Resource Recovery as a circular business model recovers usable materials from product waste to create new inputs and products. Examples of common circular production systems include: recycling pulp-and-paper-mill waste into renewable plastics and textiles, recovering precious metals from batteries to be used in house appliance manufacturing, and creating energy from organic materials. All of these models aim to retain value of the initial material extracted, while reducing costs across economic, social, and environmental domains. Industries that include circular business models in their product/service design automatically create additional value not only for their business and their customers, but also for society and environment.

Environmentally, resource recovery significantly values the environment by reducing landfill waste and conserving natural resources. It also lowers energy consumption and greenhouse gas emissions by decreasing the need for new materials through drilling, mining, or extraction, and preserving health of the landscape for ecosystems and people.

Socially, integration of resource recovery models into our production systems can significantly impact communities and society. They reduce pollution and waste and improve resource distribution, which can promote healthier living conditions for underserved populations. Additionally, by developing innovative solutions for resource recovery, these models create local jobs which improve community employment and economic stability, and raise awareness about sustainability that can foster a collective sense of responsibility.

Economically, resource recovery reduces landfill waste disposal costs and improves economic growth through job creation and technological innovation. It also reduces extraction and production costs by minimizing the need for new raw materials, driving industry efficiency and long-term sustainable business development.

According to Value Chain Management International, nearly 60% of food produced for Canadians is lost and wasted annually. That’s nearly 36 million tons of food – equivalent to a financial value of $50 billion. This staggering number has sparked a growing societal awareness around the issue of food loss and waste, and the vital need for overhauls in how we manage resources, materials, products, and waste within our food systems.

The concept of food and organic waste recovery through a circular business model introduces a transformative approach to managing and repurposing surplus and discarded food and organics. Within this model, food and organic waste is not just discarded to landfill but is instead redirected through a network of recovery and redistribution systems. The focus is on converting what would otherwise be wasted into valuable resources, such as compost, animal feed, or bioenergy to retain as much of the original value of the food materials as possible.

Municipalities, businesses, consumers, and organizations can collaborate within closed-loop food systems to ensure that food waste is efficiently collected, processed, and reintegrated back into the supply chain. This approach aligns with circular economy principles, aiming to minimize environmental impact, reduce landfill use, create positive community impacts, and improve resource management by keeping food materials in productive, higher-value use.

It’s also vital while redesigning our current systems to adopt more circular practices, that they are intentionally designed, not just for larger industry stakeholders, but also access to these systems and services for small-and-medium enterprises (SMEs) and consumers to participate in food and organic material recovery as a circular practice.

New models for food waste reduction and organic waste diversion for SMEs are being piloted across Canada through CIC’s Commercial Food Waste Diversion Pilots. This program helps SMEs access food rescue and organics collection services by offering a collective membership that leverages economies of scale and group buying power, making organics collection simpler and more affordable for businesses. The pilot tailors its approach to each region, creating straightforward systems for businesses to donate edible food and access cost-effective composting options for inedible food. These resource recovery strategies maximize the value of recoverable food and organic waste, turning them into donated food for communities and compost to enrich local soil health and support food production. These practices support closed-loop circular food practices for municipalities and businesses.

Walker Industries exemplifies leadership in the circular economy transition, leveraging resource recovery to drive sustainable practices and reduce waste.

As one of Canada’s largest composting, packaging, and organic waste recovery companies, Walker diverts over 1.1 million tonnes of waste annually from landfills, converting it into products like organic fertilizers, compost, mulch, and renewable natural gas. This process not only reduces landfill usage but also recovers valuable resources, supporting environmental sustainability.

Walker’s composting facilities in Thorold and Arthur, Ontario, utilize a combination of open-windrow composting and the GORE® Cover Composting System to process and manage organic materials. These sites accept a range of compostable materials and leaf and yard waste from residents, municipalities, and industrial, commercial, and institutional partners.

Walker’s subsidiary, All Treat Farms in Arthur, ON operates one of Canada’s largest state-of-the-art composting facilities and embodies the resource recovery principles of a circular economy in action.

The compost produced here is used as the primary ingredient in Walker’s premium lawn care products and garden soil amendments, which re-enter the supply chain through sales to major retailers like Walmart, Home Hardware, and Metro, under private label or Walker-branded product lines, eventually reaching household gardens. Walker has also engaged in the resale of the compost in bulk to its municipal clients, and a portion of the compost is sold directly to farms and agricultural communities, supporting soil health. By reintegrating food and organic waste into the economy, valuable resources embedded in these materials are recovered.

Walker is the only fully integrated North American company that processes reintroduced residential food waste and returns the value-add product (compost) back into the supply chain through bagged product sales, creating a closed-loop on food waste. In 2024, Expanded All Treat Farms Composting Facility: includes a $25-million boost to its composting infrastructure on the 130-acre property as well as an $18-million packaging facility officials say will allow the company to better recover over 170,000 tonnes of organic material and turn it into high-quality compost and soil each year.

In 2024, Walker processed over 230,000 tonnes of organic materials into compost and introduced a peat-free line of soils and mulches called “GrowBetter Gardens™” This initiative reflects Walker’s commitment to reducing its dependence on peat, a common fossil-derived material in soil amendments, thereby mitigating impacts on peatlands—valuable ecosystems known for carbon sequestration and biodiversity. By replacing peat with compost, Walker is actively contributing to the preservation of peat bogs and the diverse habitats they support.

As an organic amendment, compost offers numerous agronomic and environmental benefits over fossil-fuel-based soil enhancers. A key advantage lies in its ability to restore Ontario’s topsoil, which is generally low in organic matter and suboptimal in pH for effective water retention and plant health. Organic matter in compost releases essential nutrients, such as nitrogen, phosphorus, and sulfur, through natural processes, reducing dependency on synthetic fertilizers and the environmental toll of resource extraction. Additionally, compost improves soil structure by enhancing water-holding capacity, increasing permeability, and reducing erosion.

The water-retentive properties of organic matter allow it to hold up to 90% of its weight in water, releasing moisture gradually as plants require, thereby supporting plant resilience and promoting sustainable growth. Through these benefits, compost not only contributes to healthier soils but also aids in sustainable land management practices, aligning with broader environmental conservation goals.

Geoff Boyd, Vice President of Resource Recovery states one of the principal strategic goals of Walker Industries as a company is to be “a North American-scale leader in recovering resources.”

Sahra Shojaei, Business Development Lead of Resource Recovery, says, “Walker is committed not only to effective front-end material processing but also to maintaining the highest quality in our final products. This dedication strengthens the business case for closing the loop on food waste and returning materials to the supply chain in a cradle-to-cradle approach.”

Ontario’s available landfill capacity is projected to be exhausted by the year 2036. However, if legislative or economic changes lead to a halt in exporting waste to the United States, Ontario’s landfill capacity could be depleted even sooner—by 2032, or in approximately 10.5 years. Many other Canadian provinces are confronting similar landfill capacity challenges.

Furthermore, the Food and Organic Waste Policy Statement in Ontario mandates that by 2025, most municipalities must implement green bin programs to divert food and organic waste from landfills. This initiative is critical, as over 60% of Ontario’s food waste currently ends up in landfills, generating methane—a greenhouse gas significantly more potent than carbon dioxide. Developing new robust compost facilities can be challenging for some jurisdictions due to economies of scale, as many municipalities lack the necessary investment and volume of waste to support such facilities. Walker’s existing integrated composting facilities are uniquely positioned to support municipalities in expanding or launching their green bin programs. By providing reliable processing services, Walker ensures that organic waste is effectively managed, transforming it into valuable compost and contributing to regional and provincial waste, climate, and circular economy objectives.

When exploring material resource recovery opportunities, municipalities and businesses can unlock significant value by shifting their focus from waste disposal to viewing waste as a resource. This involves identifying potential recovery points and developing strategies to create marketable, high-quality end products from existing materials.

In the journey to establish effective waste-to-resource recovery programs, municipalities and industries should prioritize ‘end-product quality’ as a foundational element. While it’s common to focus on regulatory compliance and front-end waste processing, a more effective approach is to first determine how to produce a high-quality end product from the available ‘waste’ resources. This entails conducting thorough market research and understanding the value that high-quality, circular end products—such as premium compost—can bring to various sectors.

Once municipalities have a clear vision of the desired end-product quality and target market, they can develop the necessary systems and processes to achieve these goals. Utilizing organized small and medium-sized enterprise (SME) buying power can be a valuable tool in generating interest and fostering the adoption of new end-product markets. Ultimately, this approach ensures that waste management programs incorporate resource recovery practices and yield products that are efficient and beneficial to the community, the environment, and the regional economy.

We respectfully acknowledge that we live, work and play on the traditional territory of many Indigenous Nations and we humbly extend our respect to Indigenous individuals, communities and Elders, past and present, as the traditional custodians of this land.

Circular Innovation Council is a registered charity.

Charity Registration Number: 119112118 RR 0001